Category

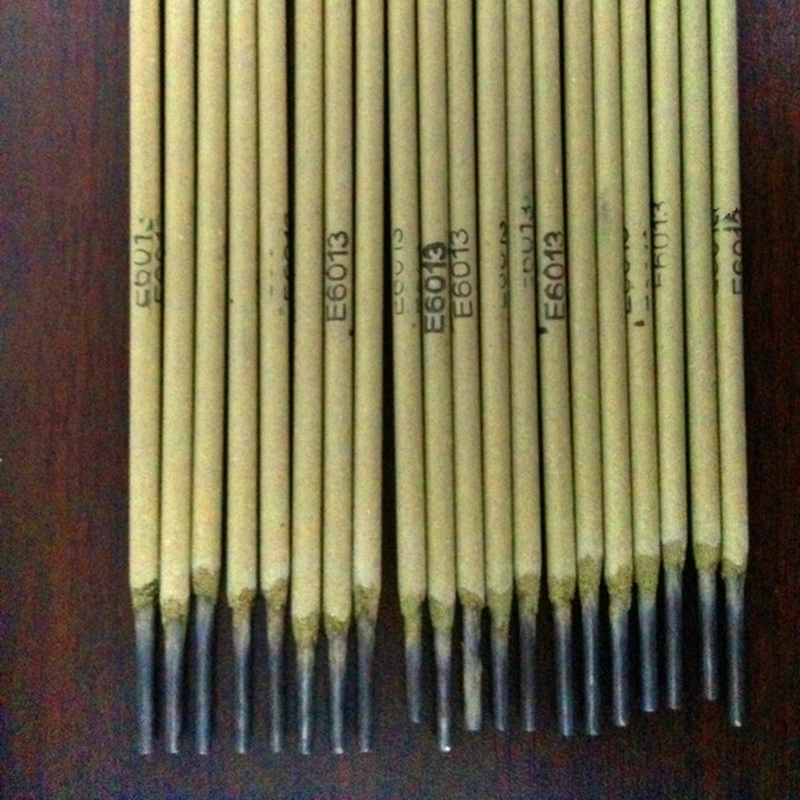

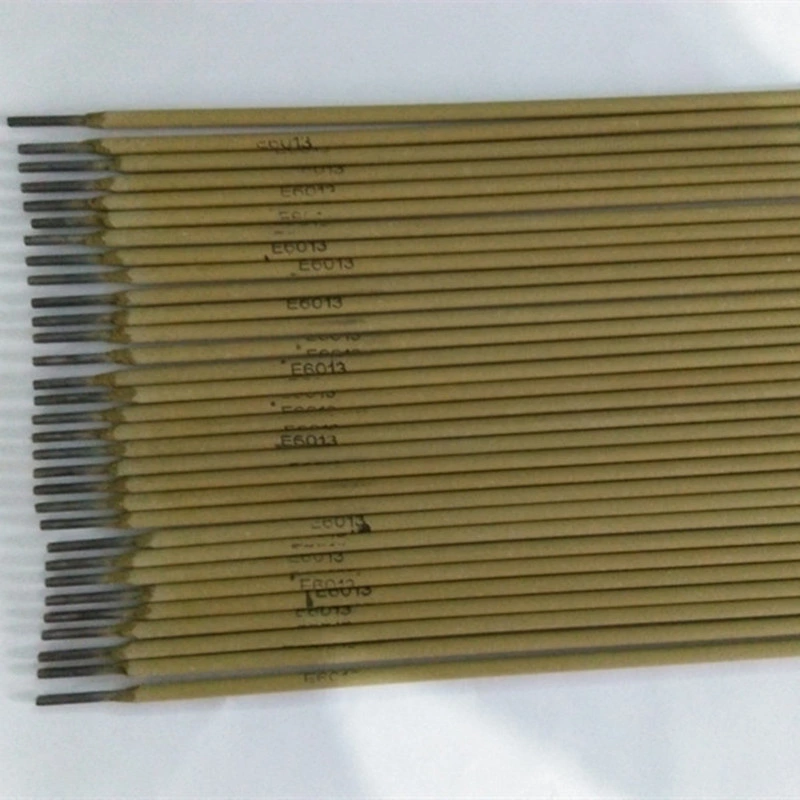

Consumables Soldering Rod Customized Welding Material E6013/GB E4313/J421 Easy Arc Titanium Oxide Coating (E6013) DC/AC J421

Acid Carbon Steel Electrodes E6013 According with GB E4313 Introduction: E6013 is a kind of carbon steel electrode with

Basic Info.

| Slag Characteristic | Acidic |

| Function | Surfacing Electrode, Low Hydrogen Type Electrode, Hardfacing Electrode, High Efficient Iron Powder Electrode, Gravity Electrode, Moisture-Proof Electrode |

| Welding Power | DC/AC |

| Colour | Accept Customized |

| Transport Package | 2.5kg/5kg Per Box; 20kgs/Carton |

| Specification | 2.5*300/2.5*350/3.2*350/4.0*400 |

| Trademark | OEM |

| Origin | China |

| HS Code | 8311100000 |

| Production Capacity | 50000ton/Month |

Product Description

Acid Carbon Steel ElectrodesE6013 According with GB E4313

Introduction: E6013 is a kind of carbon steel electrode with titania type coating. AC/DC All-positionwelding. lt has excellent welding performance, excellent operating performance, easy re-ignition,stable arc and smooth welding appearance.

Applications: Suit for welding general low-carbon steel structures, especially suitable for welding smallsize thin plates, intermittent welding with short weld heads and cosmetic welding that requires smooth weld beads.

Chemical Composition of Deposited Metal(%)

| Chemical Composition | c | Mn | si | s | p |

| Guarantee Value | <0.12 | 0.3~0.6 | <0.35 | ≤0.035 | ≤0.040 |

MechanicalProperties of Deposited Metal

| Test ltem | Rm(MPa) | ReL(Mpa) | A(%) | KV2(J) | KV2(J) |

| Guarantee Value | ≥420 | ≥330 | ≥17 | -(normal temperature) | -(0ºC) |

| General Result | t460~540 | ≥340 | 18~26 | 50~80 | ≥47 |

X-ray RadiographicInspection:IDegree

Reference Current(AC,DC)

| Electrode Diameter(mm) | Φ2.0 | Φ2.5 | Φ3.2 | Φ4.0 | Φ5.0 |

| Welding Current(A) | 40~70 | 50~90 | 90~130 | 130~210 | 170~230 |

Packing details:

In carton of 20kgs/net, consisting of 8 boxes x 2.5kgs for 2.5mm, & 4 boxes x5kgs for other sizes.With/wewithout pallets (Fumigation-free pallets) upon customer's request.